Estas inovações serão apresentadas pela primeira vez, antes de estarem comercialmente disponíveis, na exposição em Milão, Itália, solidificando o compromisso da Mimaki com soluções sustentáveis e amigas do ambiente na indústria de impressão têxtil.

Introducing Mimaki's new textile pigment transfer printing system—a response to the need for environmentally conscious textile printing

Tradicionalmente, o processo de tingimento de fibras naturais gera uma quantidade alarmante de águas residuais – cerca de 2 bilhões de toneladas todos os dias nos processos de pré e pós tingimento em todo o mundo – e contribui significativamente para as emissões de CO2. Além disso, o processo de tingimento é complicado em termos de estrutura e processo de equipamentos e, frequentemente, o transporte internacional de produtos têxteis a partir dos principais países produtores de têxteis também emite CO2. O Sistema de impressão por transferência de pigmentos têxteis minimiza o uso de água e simplifica o fluxo de trabalho de impressão. Adicionalmente, o seu tamanho compacto e preço acessível permitem a implementação local da produção de pequenos lotes de têxteis, levando à redução significante do impacto ambiental.

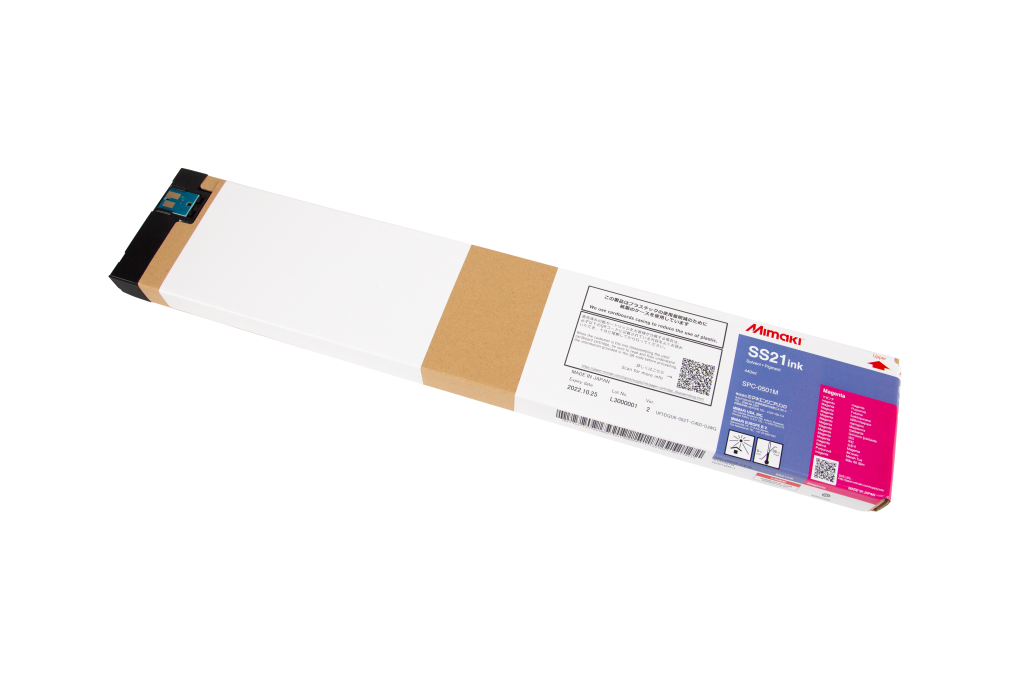

Arjen Evertse, General Manager Sales at Mimaki EuropeThe transfer printing method is more sustainable than analog and digital textile dyeing methods, with no water consumption and substantially lower CO2 emissions. The system, demonstrated at the Mimaki stand (H7-C304), consists of three essential elements: Pigment Ink for Textiles, the Transfer System, and Texcol Textile Pigment Transfer Paper.

Texcol is a revolutionary transfer paper developed by Dutch paper manufacturer Coldenhove that enables the transfer of a digital print via an environmentally friendly 3-step transfer process to create a vibrant application on a wide variety of materials, including natural fibers. The design is initially printed onto the paper using a customized TS330-1600—Mimaki's high-volume, high-quality dye sublimation printer—and Mimaki's new pigment inks developed for the process. The module that adapts the TS330-1600 will be available as an option for existing and new Mimaki customers in the third quarter of 2023, but is previewed at Mimaki's ITMA booth, giving visitors a first-hand and exclusive look at how this highly productive Mimaki printer can be transformed into Mimaki's most sustainable solution to date for apparel, home textiles, and soft signage.

Mimaki's new Pigmented Textile Ink is currently undergoing bluesign certification before becoming commercially available. bluesign is a prestigious certification program that ensures the highest levels of safety, environmental friendliness, and sustainability in the textile and apparel industry.

Na etapa final, o papel Texcol passa por um processo sem água numa calandra de nível de entrada, sobre o tecido escolhido.

Another pioneering innovation from Mimaki – Cyclical textile technology

A Mimaki também está a lançar o seu inovador e único Processo Neo-Chromato, que revoluciona a reutilização de têxteis de poliéster coloridos.

Growing awareness of sustainability has created a major disposal problem in the textile industry, with polyester textiles accounting for approximately 60% of the 92 million tons of textile waste worldwide. Of this enormous amount of polyester waste, only about 15% is currently recycled. Mimaki's Neo-Chromato Process addresses this problem by using a decolorization technology for dye sublimation inks. The process not only eliminates the need for incineration of polyester waste, but also reduces the energy consumption associated with textile recycling.

Arjen Evertse, General Manager Sales at Mimaki Europe

By decolorizing polyester textiles dyed with dye sublimation technologies, this innovative process allows materials to be reprinted or re-dyed immediately, contributing to a smaller circular economy. There is no limit to the number of times reused polyester can be treated with the Neo-Chromato Process. The process itself minimizes water use and pollution, allowing the elimination of absorbent paper and bleaching solvents used in the process as incinerable waste.

It is the responsibility of everyone here at ITMA and in the textile industry in general to contribute to a more sustainable future. Mimaki actively collaborates with retail and apparel brands to explore the full potential of our latest sustainable technologies. While these latest innovations enable significant advances in sustainable textile production, we also remain focused on bringing more innovations to market that respond to the urgent needs of our customers, designers, brands, and, most importantly, the planet.

Arjen Evertse, General Manager Sales at Mimaki EuropeMimaki's high-volume, high-quality dye sublimation printer TS330-1600 can print on Texcol using the company's new pigment inks that have been specially developed for this process.